Sustainable Future for Furniture!

One of the most important features that sets Vepa apart is its eco-friendly production approach. Vepa has been manufacturing environment friendly furnitures in its factories in Hoogeveen and Emmen since 1951. Vepa is operating in a total surface area factory of 60,000 m2 in Netherlands. From the finest details, everything is produced in Vepa facilities and they work on furniture parts in the tool shops that last forever.

Vepa could even recreate furniture with the old moulds they still have which are from the very beginning of their company. Vepa has taken its production operations to the next level with the Circular Center it has put into operation in Emmen, Netherlands. Thanks to this center, its sustainability-focused production philosophy has reached the highest level.

Pioneering Circular Furniture

Vepa boasts a state-of-the-art Circular Center in Emmen, Netherlands, where they breathe new life into furniture products, giving them a second or even third chance instead of discarding them. Vepa’s commitment to circularity lies at the heart of every product they create. This dedicated facility (Circular Center), alongside Vepa’s factories, offices, research laboratories, and GreenFields, forms the core of their circular operations.

This center is where many furniture pieces come to be revitalized. The Circular Center collaborates with educational institutions, businesses, and government agencies to explore innovative ways to repurpose waste materials and develop new circular products and services. From test pieces and customer returns to exhibition stands and excess stock, they assess, store, disassemble, and refurbish furniture, giving them a new purpose. Products without a specific purpose are separated into their individual components or raw materials for reuse. This disassembly process is highly efficient and maximizes material recovery, as Vepa furniture is designed with a circularity philosophy in mind.

For More Detailed Information About Products

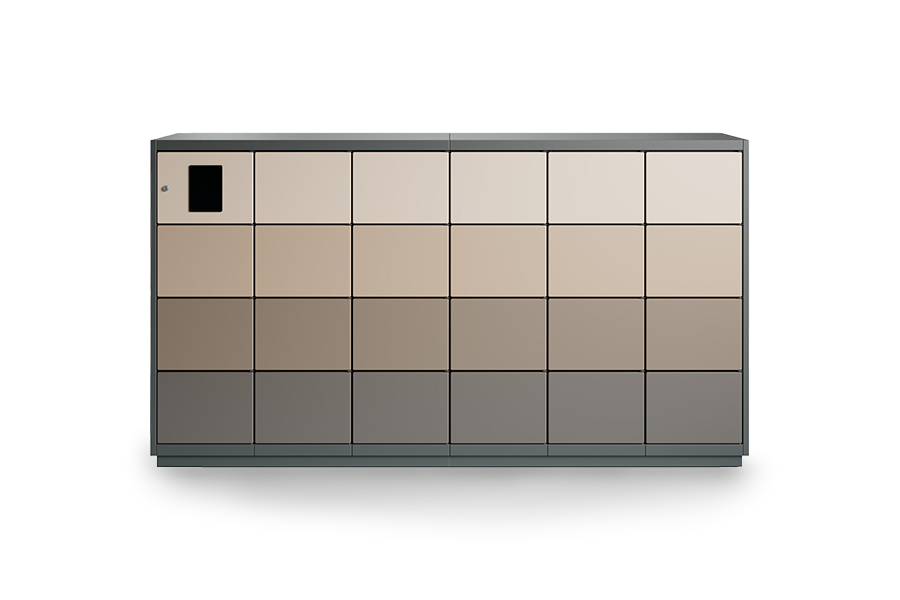

PRODUCT GROUPS

Uncompromising Quality, Renewed Purpose

Advancing Circularity Through Research